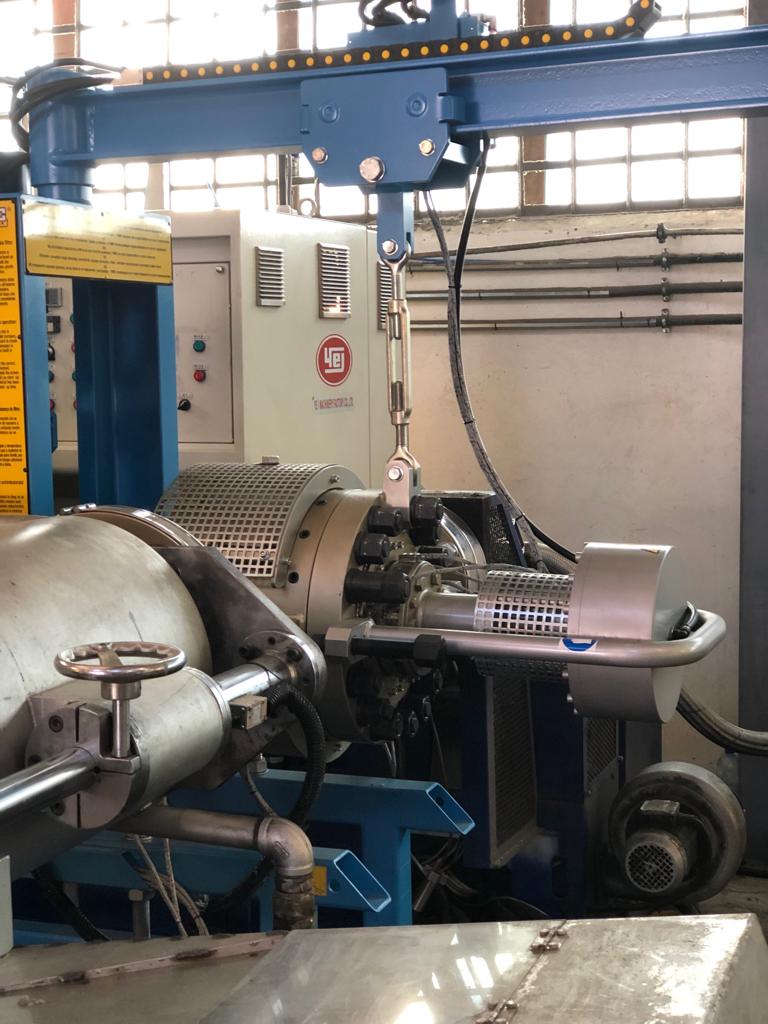

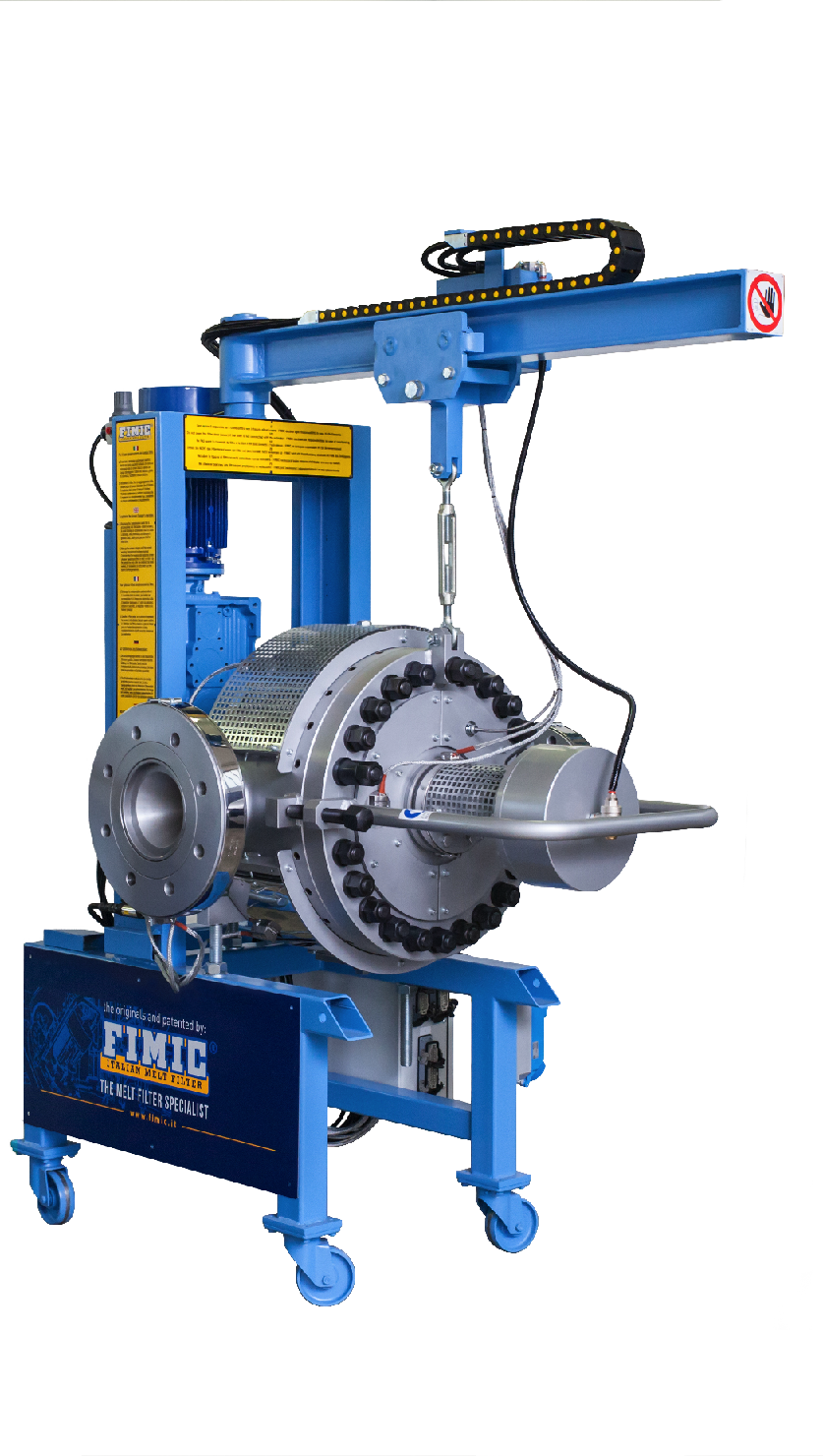

The Fimic RAS filter presents a series of innovations as its technology contains features that are not only one of a kind in the market, but also are a real help and support in the principle that should be the basis of every recycling plant: the possibility to process contaminated materials otherwise destined to either landfilling or incineration.

The Fimic RAS filter gives the possibility of being able to recycle even the most contaminated materials, giving them new life and at the same time, preventing them from being incinerated.

This is possible thanks to a technology that contains the right compromise between effectiveness and simplicity. Its operation is so simple that any operator can handle it without problems, and its configuration guarantees to the machine the necessary strength but at the same time also flexibility, to face even the most difficult materials.

Fimic's technology is based on a scraping system, where two blades are mounted, and are needed to collect (lift) the contamination from the screen into the scraper itself. In this way the screen’s surface is constantly cleaned.

The scraper consists of two arms which are hollow inside, in order to collect and retain the collected contamination. The scraper is connected directly to a discharge valve, which will open only to the pre-set parameters (of time or pressure). The cleaning phase is done automatically by the filter, and with the screen you can work continuously for days, thus reducing even more the amount of screens to be disposed, which in the case of manual or slide plate filter, is really high.

The RAS Filter also gives the possibility to use 2 different types of screens, based on the final application you want to achieve.

LASER-perforated screen: used in case of high-demanding applications (blown film, earthed pipings, etc..) requiring fine filtration. The quality that can guarantee this type of screen is not comparable with that given by the mesh used in the manual or slide plate Filters.

PPUNCHED screens: are instead used in the case of easier demanding applications like injection moulding, where a coarser filtration can be accepted. This is many times an advantage as it gives the possibility to reprocess the waste purged by the laser screen, regenerating part of the waste itself and thus reducing the final waste to be disposed of.

Fimic is the only company in the world to propose this alternative for filtration.

Thanks to the wide filtration surface, the RAS Filter can process materials at low pressure and if possible low temperature levels. This ensures constant quality, low energy consumption and the possibility to use coarser screens to obtain high quality in the final product.

With just one screen it is possible to have up to 3796cm2 of active filtration surface. Pressures and temperatures clearly depend on the polymer to process but it’s always an advantage to work with low pressure & temperature, to avoid polymer degradation and extra gas formation.

The FIMIC RAS Melt Filter also can be accessed even online in case of remote assistance needs.